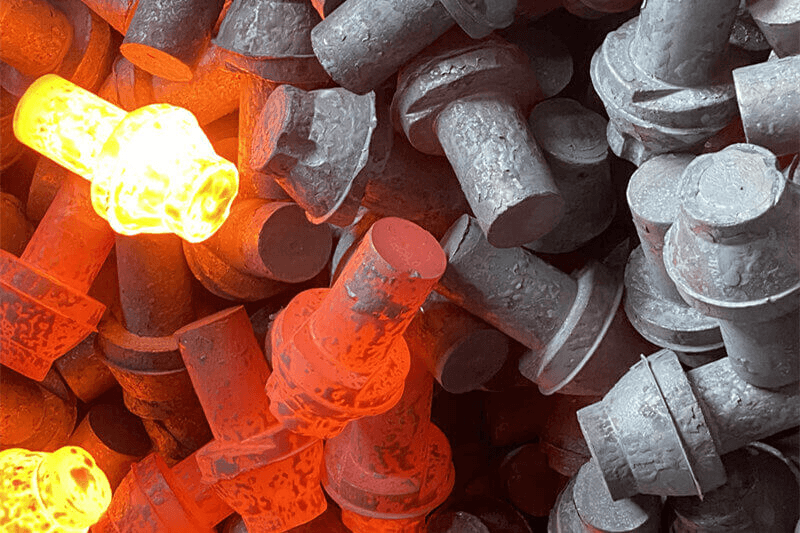

Scalable Forging Production Supporting Consistent Quality Across Critical Metal Components

Modern manufacturing depends on metal components that perform predictably under demanding conditions. As production volumes grow, maintaining identical strength, shape, and internal structure becomes essential for downstream reliability.

Industrial buyers increasingly evaluate suppliers based on how well scale and precision coexist. Production capacity alone no longer defines value without dependable consistency behind every output. Precision expectations often rise when Forging Thailand demonstrates repeatable output across demanding component requirements.

Production Scale Driving Structural Reliability

Large-scale forging operations succeed when structural reliability remains unchanged across every batch. Consistent force application, temperature control, and die accuracy ensure components behave uniformly after installation. Expansion only becomes meaningful when reliability travels intact from first unit to last. Buyers notice stability long before they notice volume figures.

Process Discipline Across High-Volume Output

High-volume forging requires disciplined execution across every operational stage. From billet preparation to final inspection, consistency relies on controlled repetition rather than speed alone. Teams managing scale understand that deviation compounds quickly without firm process boundaries.

Operational controls reinforcing output stability

- Controlled heating intervals prevent internal stress variation

- Standardized tooling preserves dimensional repeatability

- Sequenced workflows reduce handling inconsistencies

- Defined tolerances guide inspection checkpoints

- Equipment calibration ensures uniform force delivery

- Documentation tracks process accountability

When discipline anchors production, scale becomes an advantage rather than a risk. Output quality remains predictable even as order quantities increase.

Why Consistency Defines Component Trust?

Component trust forms when every delivered piece behaves exactly as expected. Engineers depend on predictable performance because surrounding systems assume uniform strength and geometry. One inconsistent batch can disrupt entire assemblies, increasing scrutiny across suppliers.

Consistency reassures buyers that production growth will not introduce hidden variability. That assurance directly influences long-term sourcing decisions.

Material Control Within Expanding Operations

Material behavior sits at the center of forging reliability, especially during expansion. Input selection, traceability, and preparation directly influence finished component integrity. As volumes increase, managing raw material flow becomes more complex yet more critical.

Material governance supporting dependable outcomes

- Verified sourcing maintains composition accuracy

- Batch segregation prevents cross-material confusion

- Pre-processing checks confirm dimensional suitability

- Storage protocols protect material condition

- Identification systems preserve traceability

- Sampling routines validate incoming consistency

Forging Thailand supports expanding demand by maintaining uniform strength across scaled component runs. Strong material governance ensures each forged piece reflects intentional handling rather than uncontrolled volume.

How Do Buyers Judge Reliability?

Buyers evaluate reliability through delivered performance rather than production claims. They observe installation results, service behavior, and variance between shipments. Patterns emerge quickly when outputs remain uniform across timelines.

Confidence Built Through Repeatable Outcomes

Repeatable outcomes build quiet confidence across engineering teams and procurement managers. When each delivery matches the last, trust forms naturally without additional verification demands. That consistency becomes a defining attribute rather than a selling point. Over time, dependable output strengthens partnerships and supports more complex component requirements. Scale then evolves from a capacity metric into a reliability signal buyers can depend on.